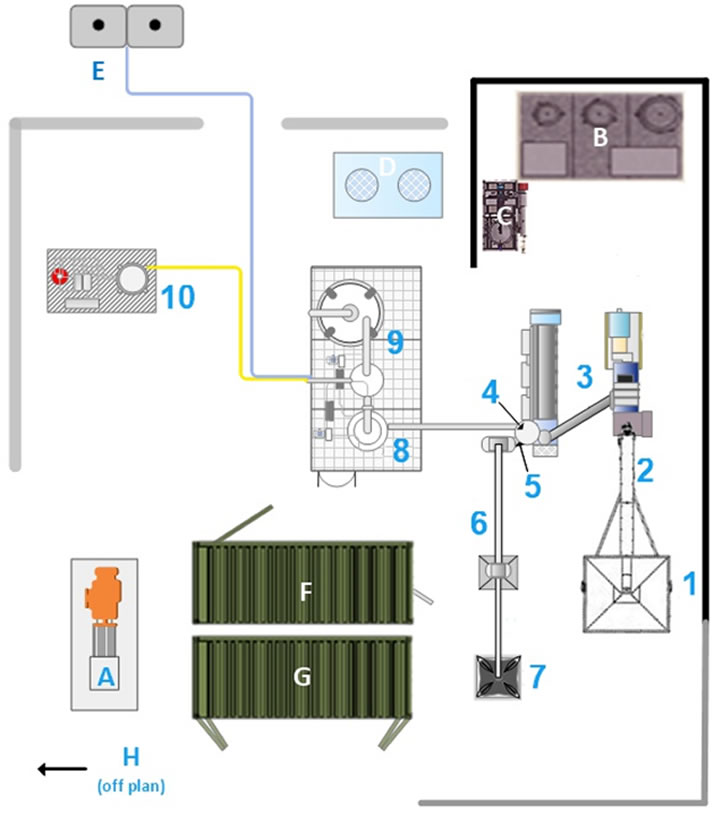

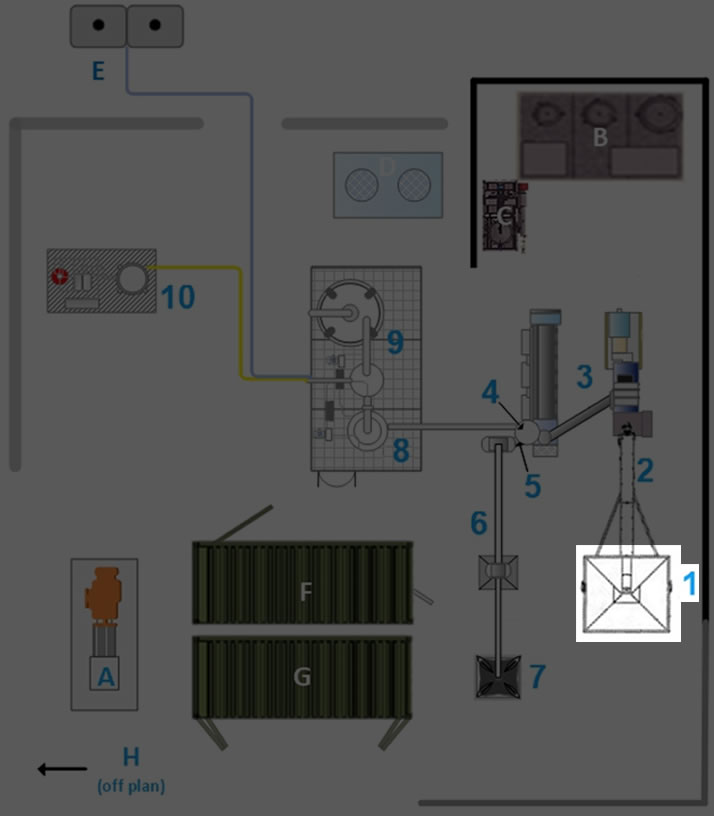

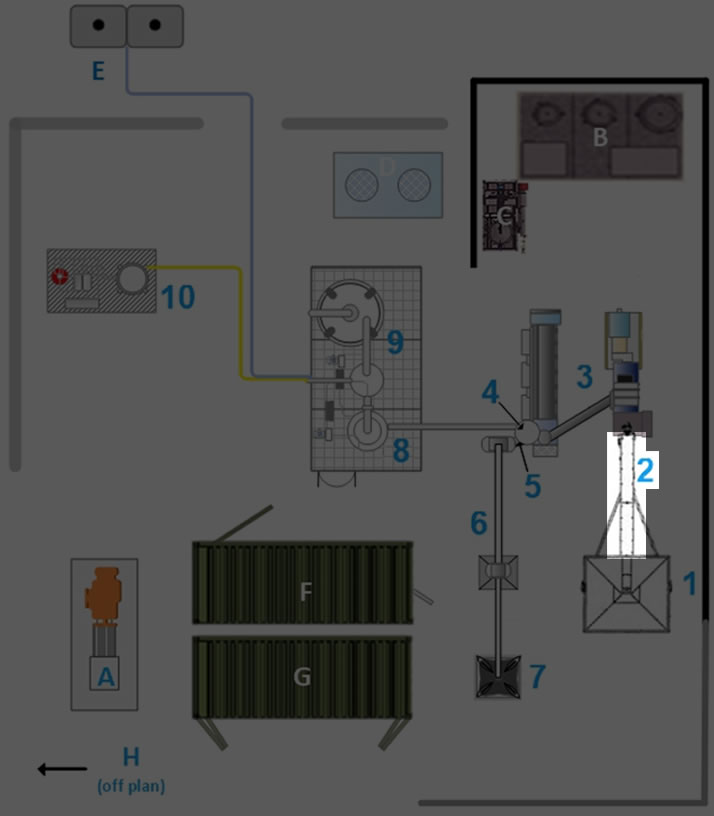

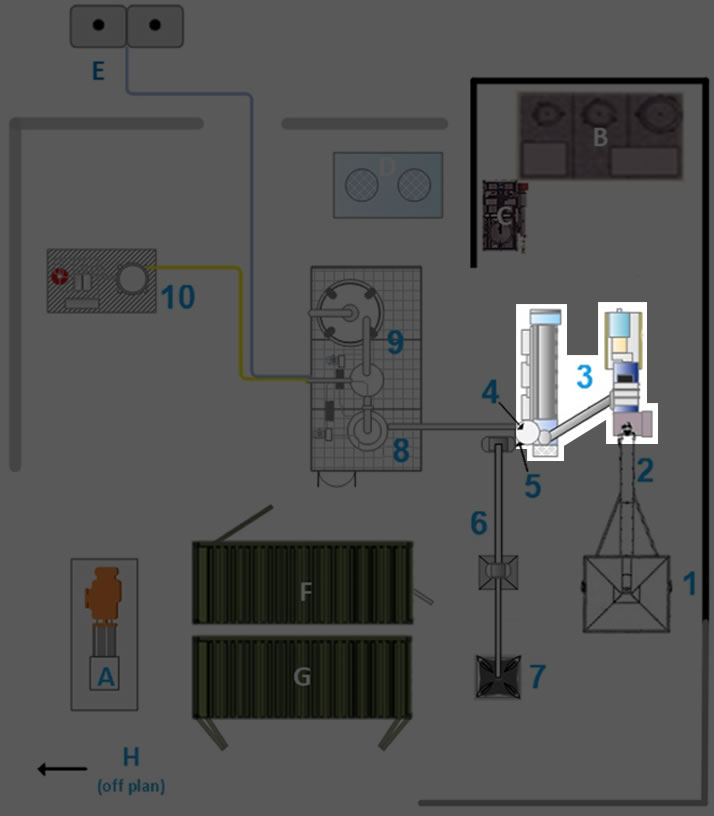

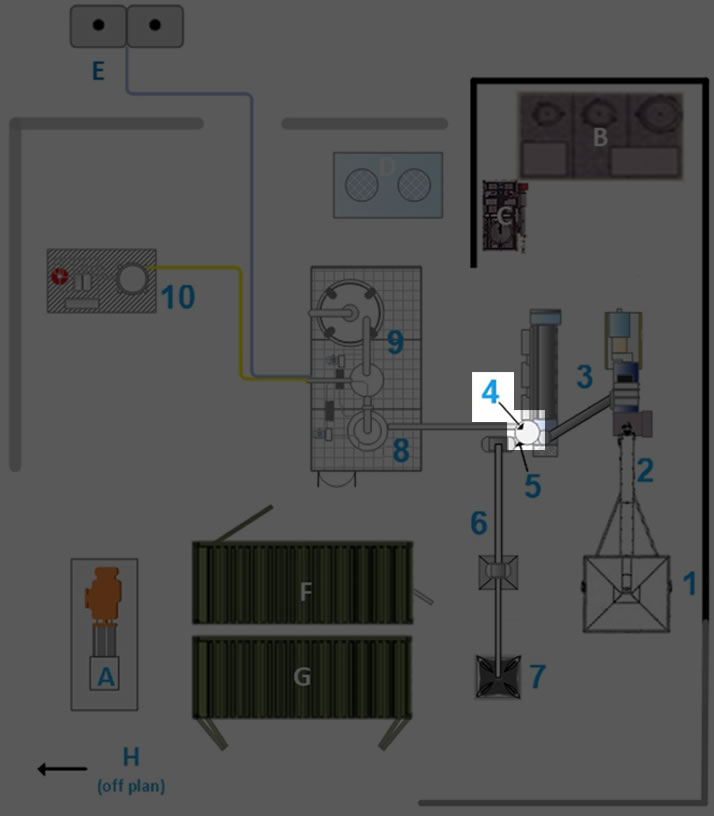

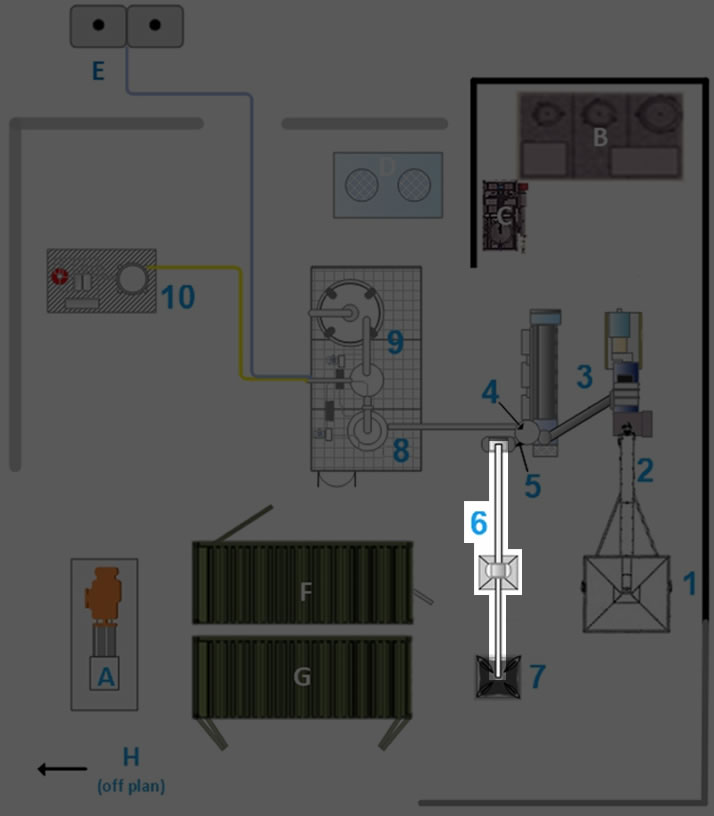

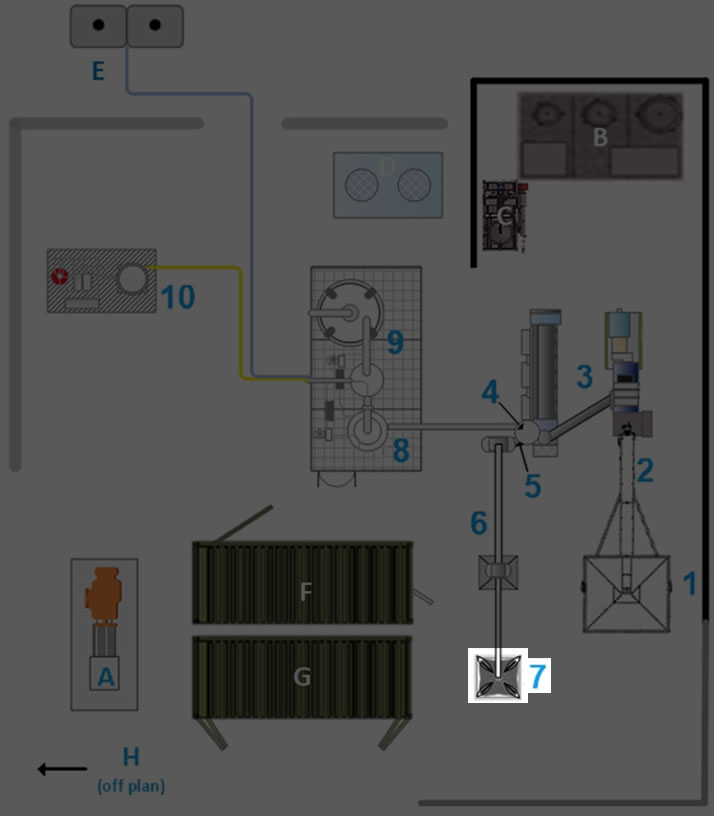

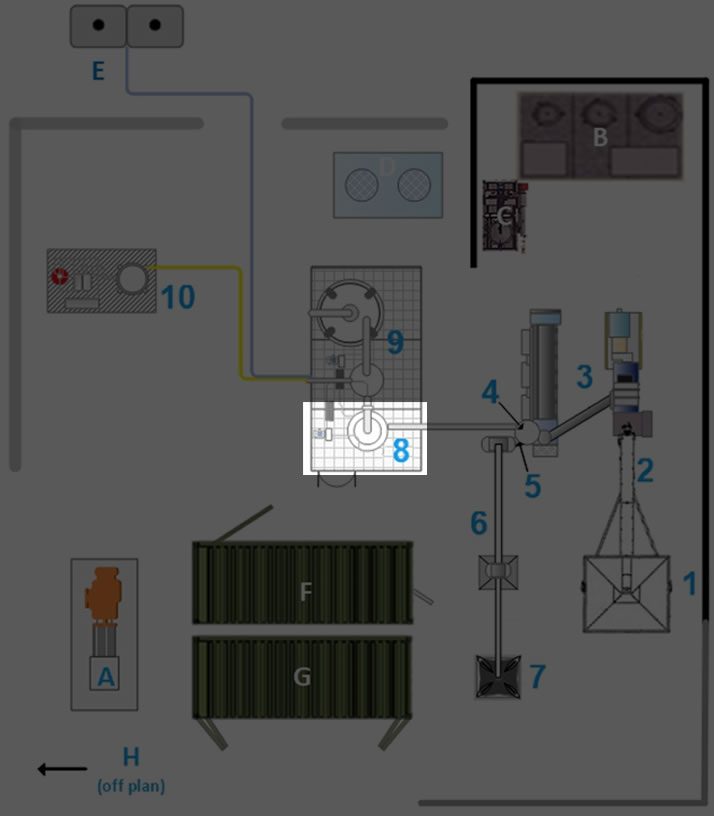

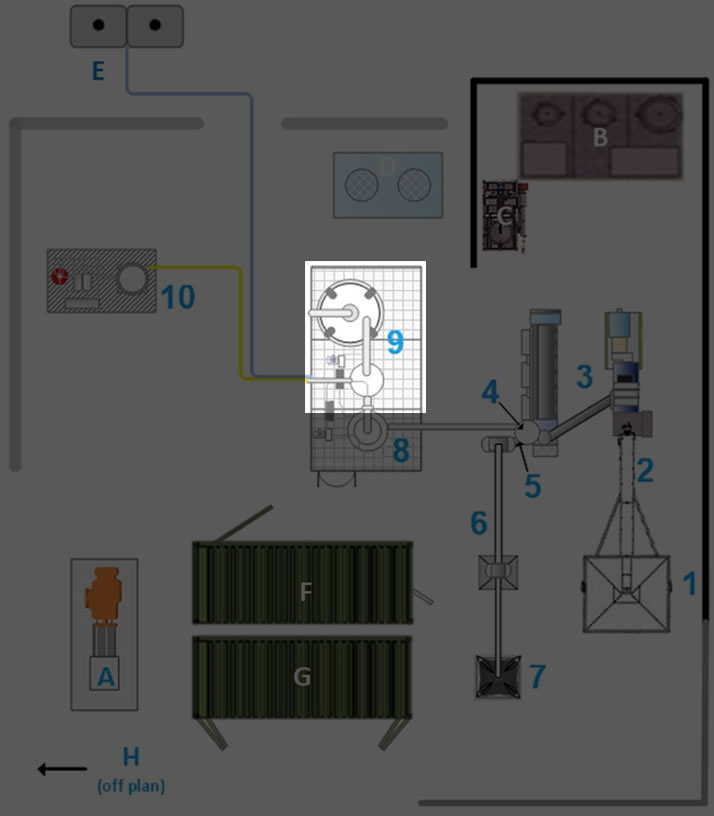

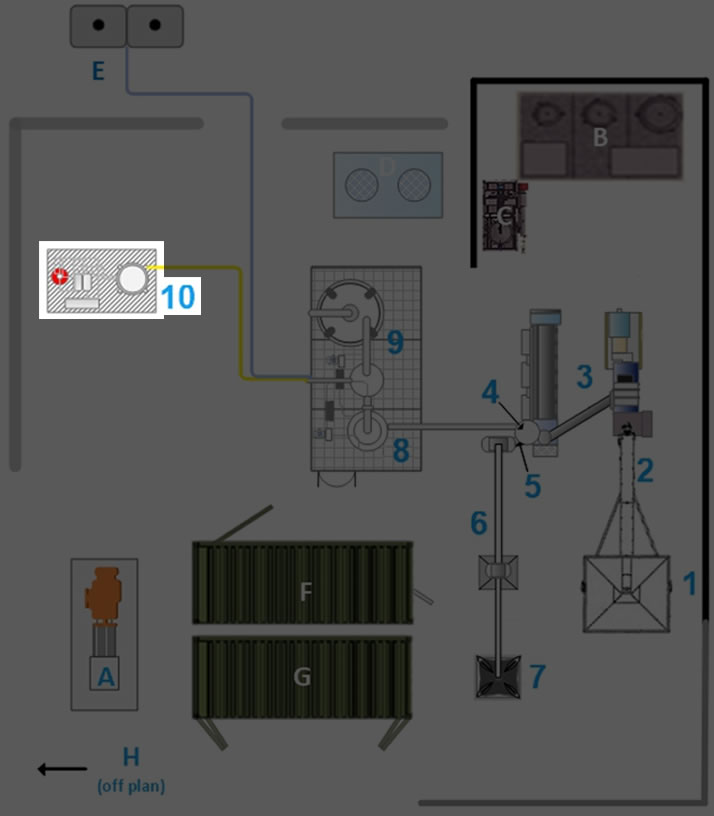

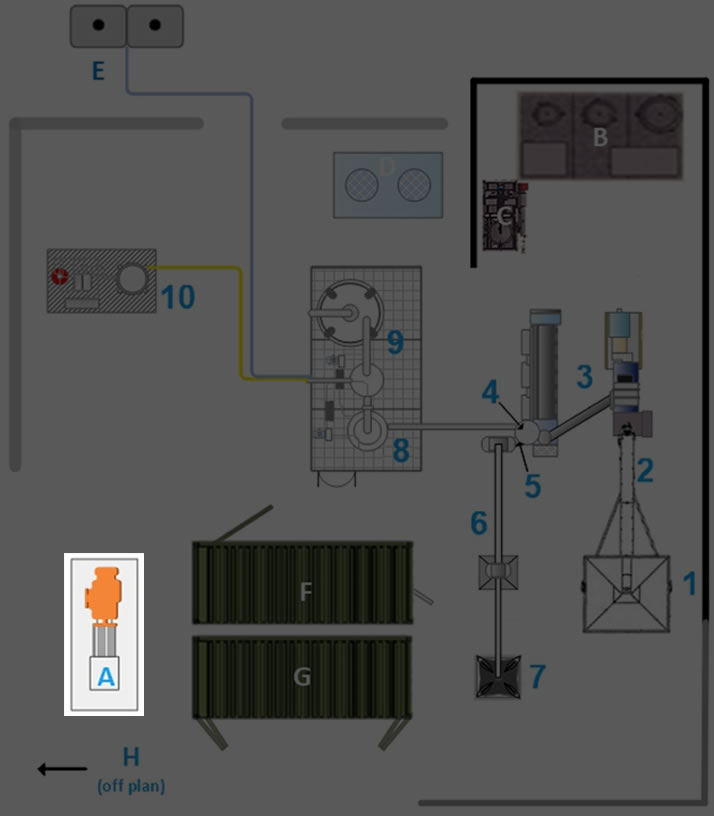

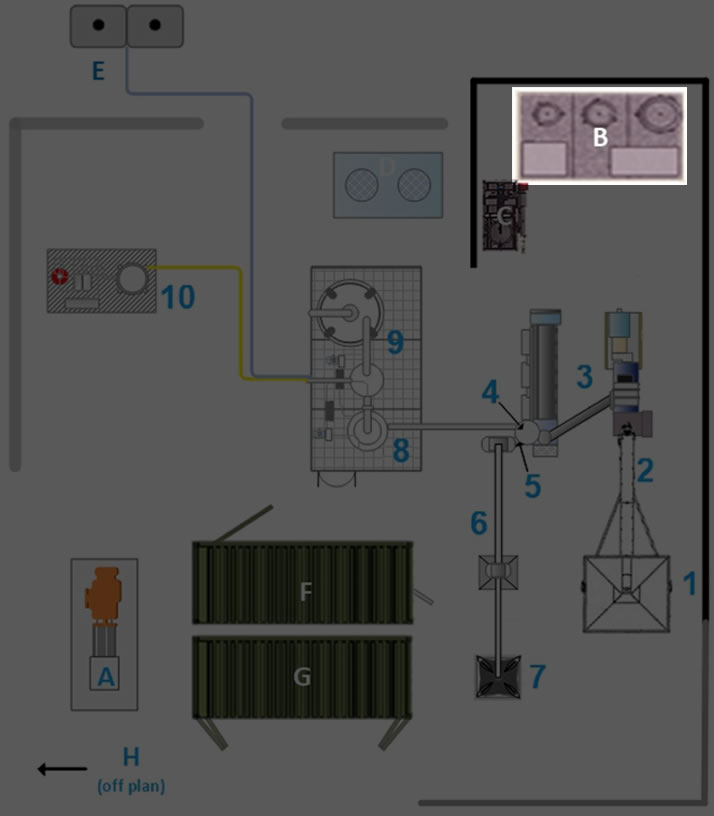

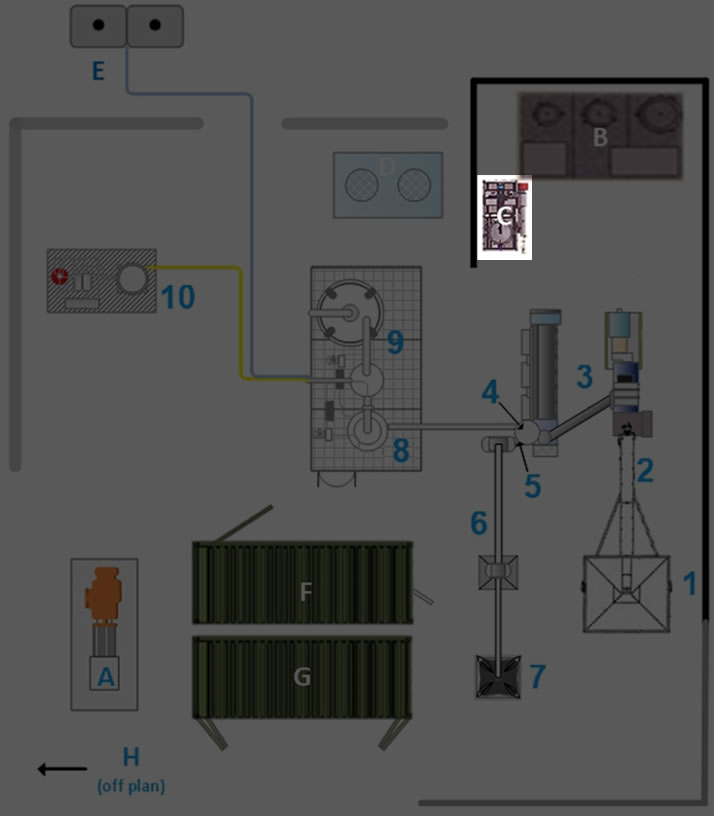

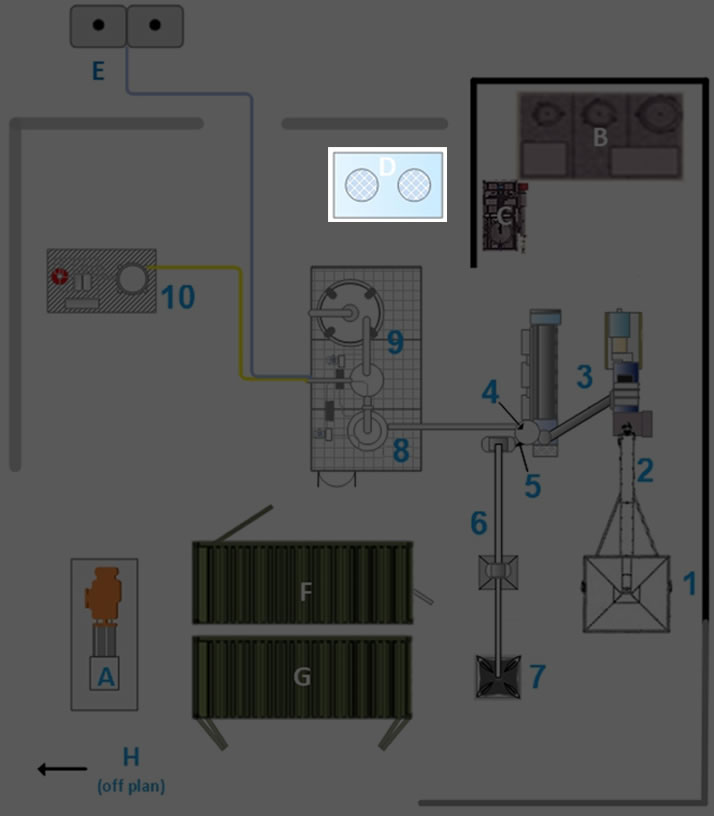

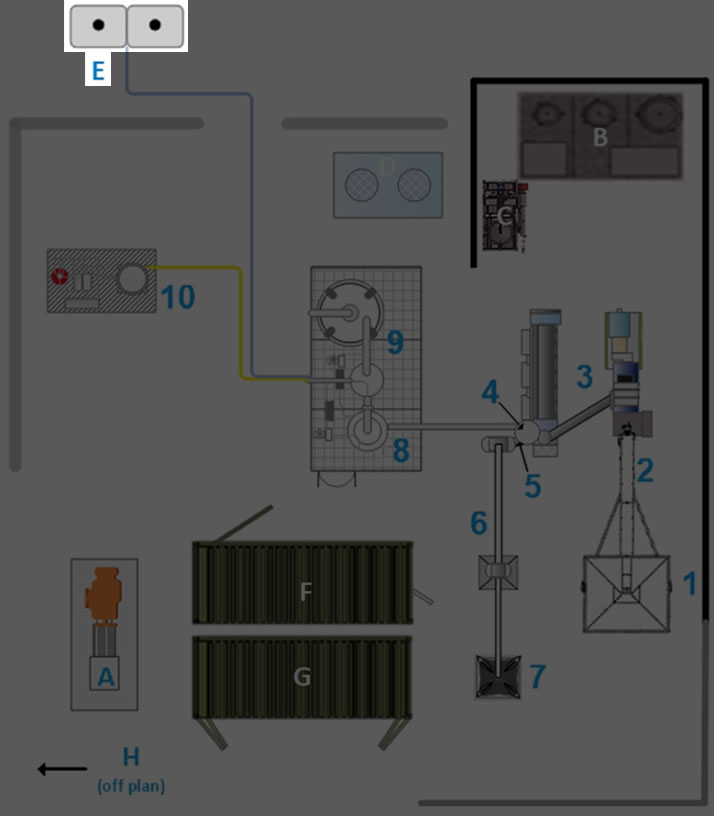

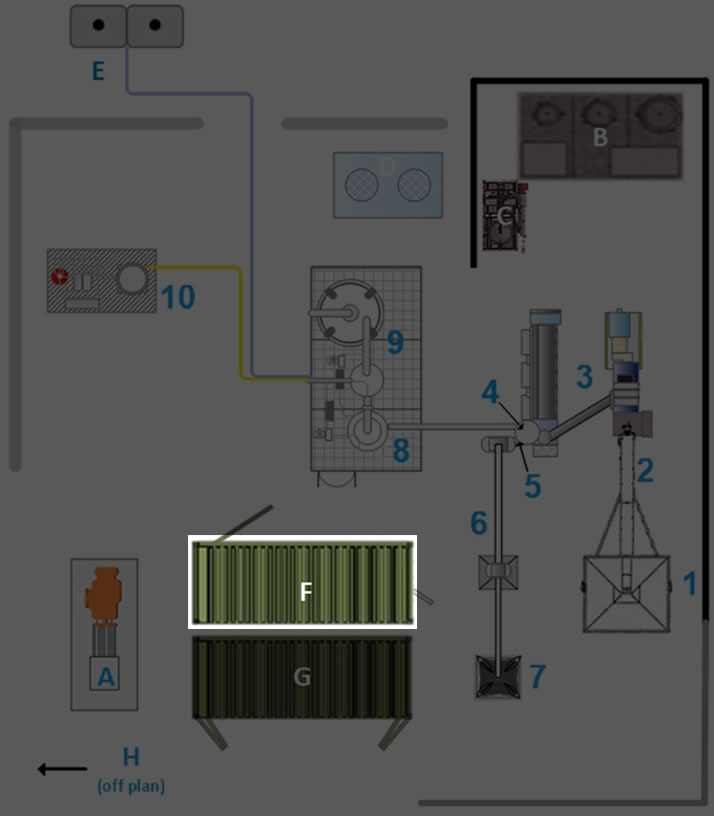

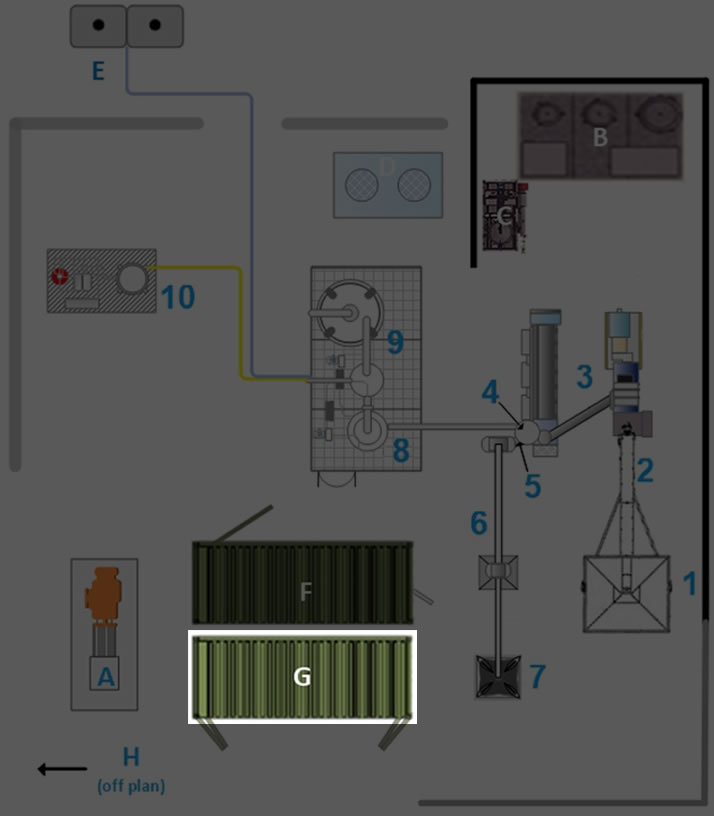

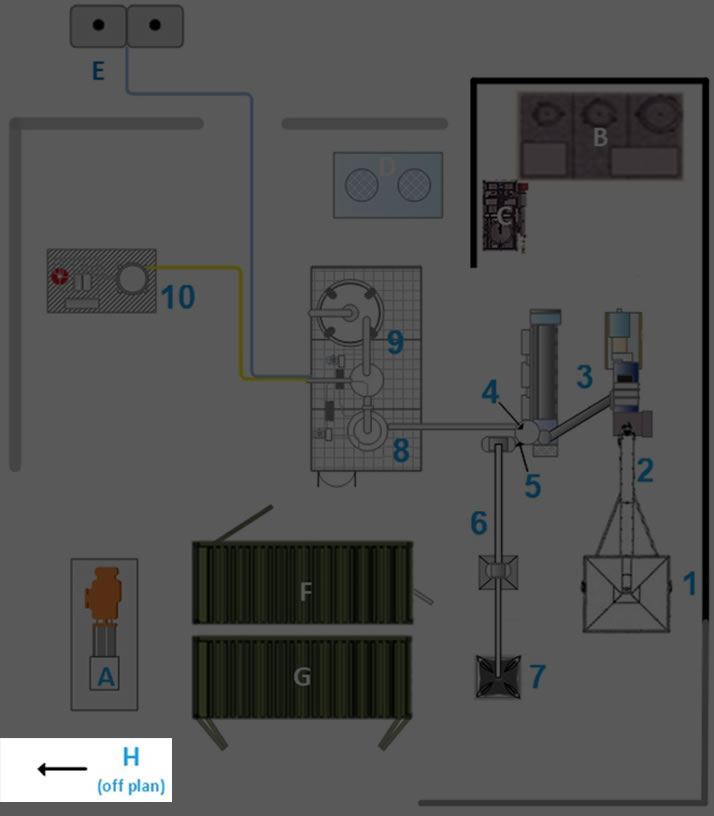

Machine Design and Schematic

The patented WF Recycle-Tech system is designed to process 1.5 tonnes of rubber from end of life tyres (ELTs) per hour, in the form of metal free rubber crumb (15-20mm), derived from passenger car tyres (however other uniform tyre types could be processed once tested).

The WF Recycle-Tech solution consists of a series of integrated modules, utilising tried and tested engineering to create a continuous innovative hybrid system, that systematically breaks down the rubber into its base compounds: a TDO (tyre derived oil), syngas and a raw recovered carbon black (rCB). Typically, 1.5 tonnes of rubber crumb produce a mass balance return of 50% TDO, 40% rCB and 10% syngas. The whole system is ATEX and HAZOPS compliant.

WF Recycle-Tech’s management team have based the production system (Generation 2) on the existing operational prototype (Generation 1), which was designed, developed and modified during an extensive research and development programme. An aerial schematic of the components included under the current prototype is outlined below with a more detailed explanation of the process available on request.

Process Equipment

- Bulk feed hopper

- In-feed auger screw & hopper

- Thermo-dynamic reactor & components

- Cyclone filter

- Raw rCB outfeed screw

- Cooling auger screw

- Raw rCB Bagging facility

- Vapour Condenser

- Gas Scrubber & storage facility

- Oxidiser (flare)

Services & Ancillary

- Generator

- Nitrogen generator

- Water heater

- Blast air cooler

- Oil storage

- Control room

- Feedstock storage

- rCB storage

Outputs and Applications

The WF Recycle-Tech system has been developed to create a recycling loop; one which serves to rid the world of a non-biodegradable waste product and produce three key commercial outputs:

TDO

TDO (tyre derived oil) is made up of a complex mixture of hydrocarbons, including a high concentration of aromatic compounds. The primary use of pyrolysis TDO is as an alternative fuel, due to its favourable hydrocarbon composition and high calorific value, which is like that of commercially available diesel, however there are many other applications available through blending or refining treatments.

Recovered Carbon Black

rCB is seen as the environmentally friendly substitute to virgin carbon black and can be applied as a sustainable reinforcing filler in tyres and other rubber products. It is also used in plastic masterbatch applications and is seen as superior to virgin carbon black when it comes to cost of production and environmental sustainability.

Syngas

The syngas produced is very much a residual output given its ratio compared to the TDO and rCB. It has high hydrocarbon levels, like that of the oil, and as such is most suited to fuel applications.

- Fuel Oil

- Blended for specific purposes

- Refined to produce Bitumen

-

Refined for chemical extraction

- Light aromatics: Benzene, toluene & xylene (used in oil refining and the manufacturing of paints, lacquers & glues)

- Monomer recovery such as Isobutene and Isoprene (Isobutene used in gasoline fuel production & fuel additives and Isoprene used in synthetic rubber production)

- Limonene (used in production of industrial solvents, resins & adhesives as well as pigments and fragrance for cleaning products)

- Reinforcing filler in tyres

- Reinforcing agent and pigment in masterbatch applications

-

Reinforcing agent in a variety of products:

- Conveyor belts, hoses, gaskets, rubber sheets, geomembranes, rubber roofing, plastics and inks.

- Coatings and inks

- Footwear

-

Fuel

- Highly calorific and can be used as a fuel to supplement the power required to run the WF Recycle-Tech system

The applications listed above open significant market opportunities for the TDO and the rCB, in particular, and highlight the potential lucrative revenue streams available. This is further emphasized when focussing on the forecast demand for both oil and carbon black as commodities especially if such products can be sourced via environmentally friendly methods.

Market Data & Forecasts

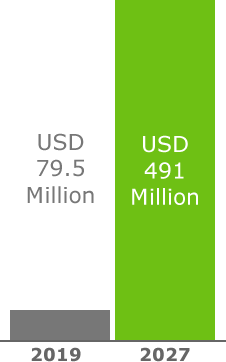

Attractive Opportunities in the Recovered Carbon Black Market

CAGR 32.6%

- The global recovered carbon black market size was valued at USD 79.5 million in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 32.6% from 2020 to 2027.

- The growth in the market is attributed to the increasing demand for recovered carbon black in tyres, non-tyre rubber, plastics, coatings and inks applications.

- North America is the largest market for recovered carbon black, with Europe following a similar trend.

Source: Global Recovered Carbon Black Market Size Report, 2020-2027. Published May 2020

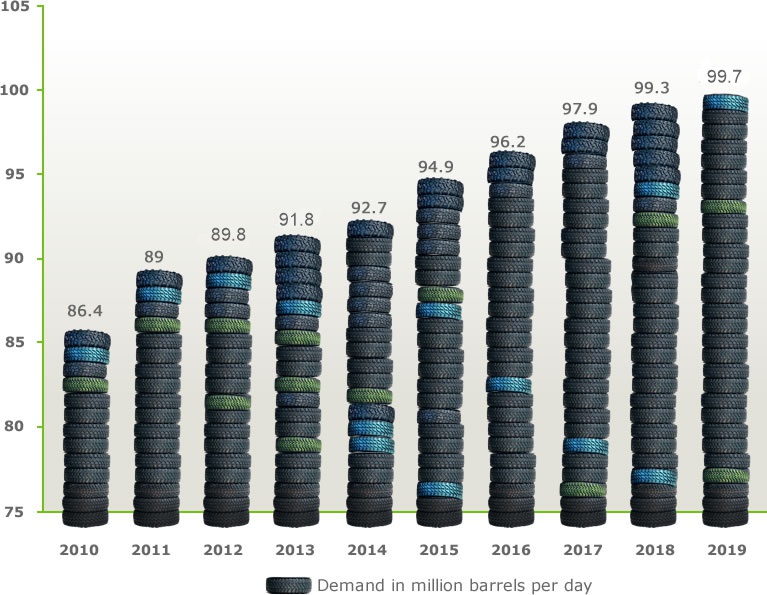

The global oil consumption also looks set to rise in the short-term following the trends of the last 10 years as illustrated in the graph below. This is despite the impact of the Coronavirus which has ultimately affected demand in early 2020 but coming through this the forecast demand is one of steady growth up until 2030.